outdoor wpc

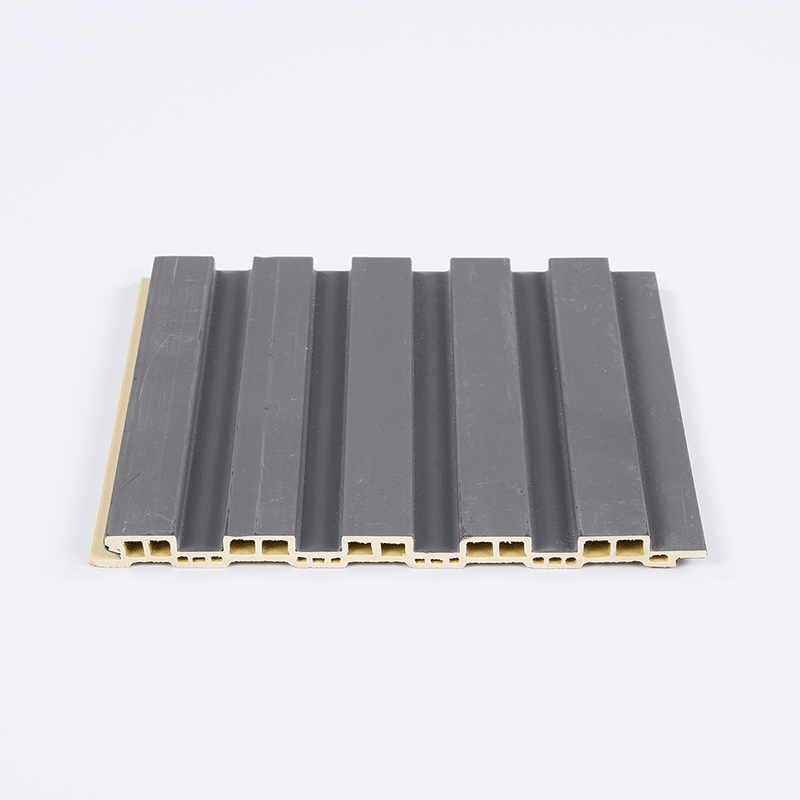

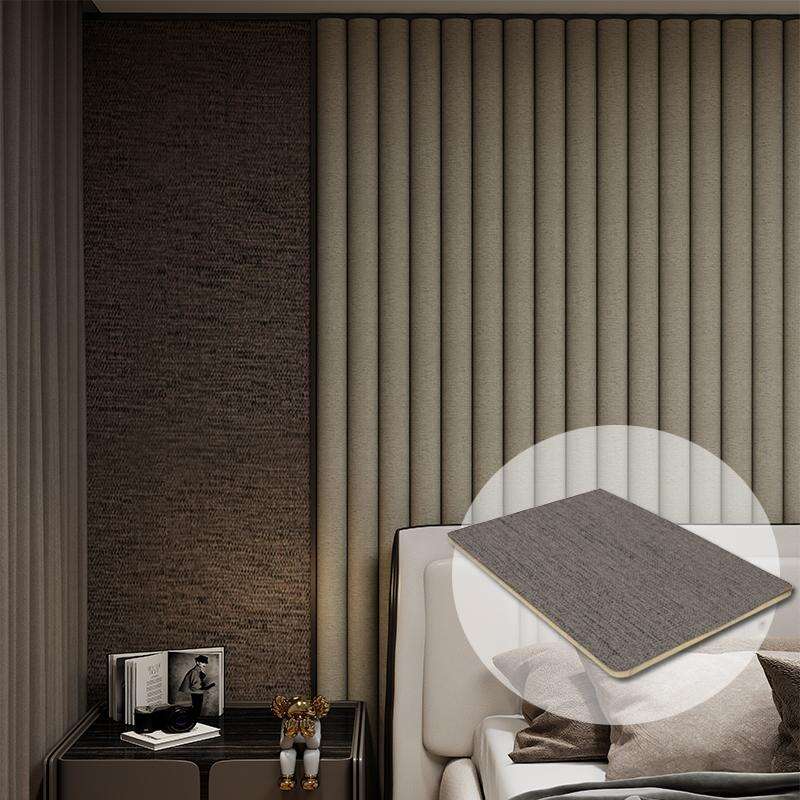

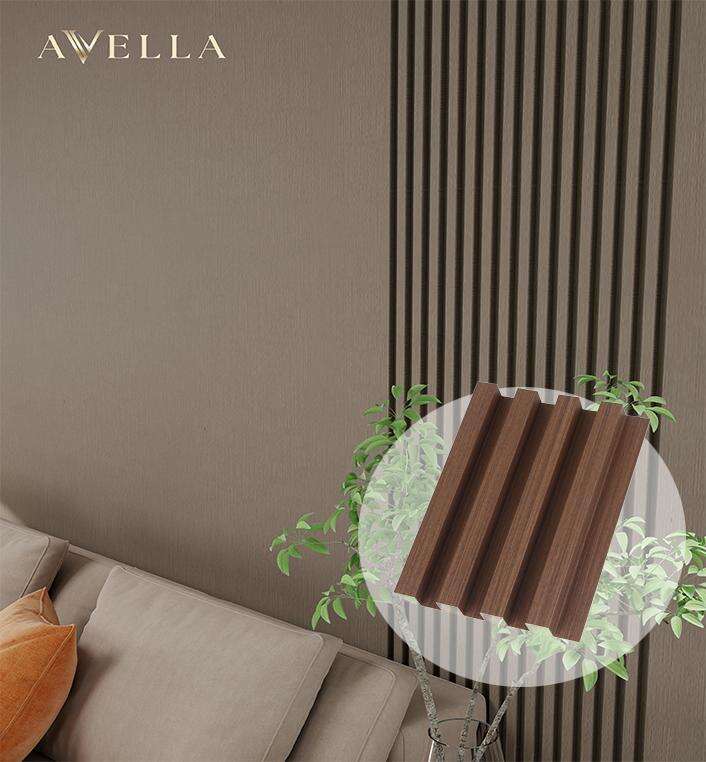

Outdoor WPC, also known as Wood Plastic Composite, represents a revolutionary building material that combines the natural beauty of wood with the durability and weather resistance of synthetic polymers. This innovative composite material is specifically engineered for exterior applications, making it an ideal choice for decking, fencing, siding, and various outdoor construction projects. The outdoor WPC manufacturing process involves blending recycled wood fibers or wood flour with thermoplastic resins, creating a uniform material that maintains structural integrity while resisting environmental challenges that typically affect traditional wood products. The technological features of outdoor WPC include advanced UV stabilization, moisture resistance, and enhanced dimensional stability. These characteristics are achieved through sophisticated polymer chemistry and precise manufacturing processes that ensure consistent quality and performance. The material incorporates specialized additives that prevent color fading, reduce thermal expansion, and eliminate the need for regular maintenance associated with conventional wood products. Outdoor WPC applications span residential and commercial sectors, including pool decking, boardwalks, outdoor furniture, pergolas, and architectural facades. The versatility of this composite material allows for creative design solutions while providing long-term performance in harsh weather conditions. The manufacturing process ensures that outdoor WPC maintains consistent density and structural properties throughout the material, eliminating weak spots and irregularities commonly found in natural wood. Additionally, the composite structure provides excellent screw and nail holding capacity, making installation straightforward for contractors and DIY enthusiasts alike. The surface texture can be customized to mimic various wood grains or achieve contemporary smooth finishes, offering aesthetic flexibility for different architectural styles and personal preferences.