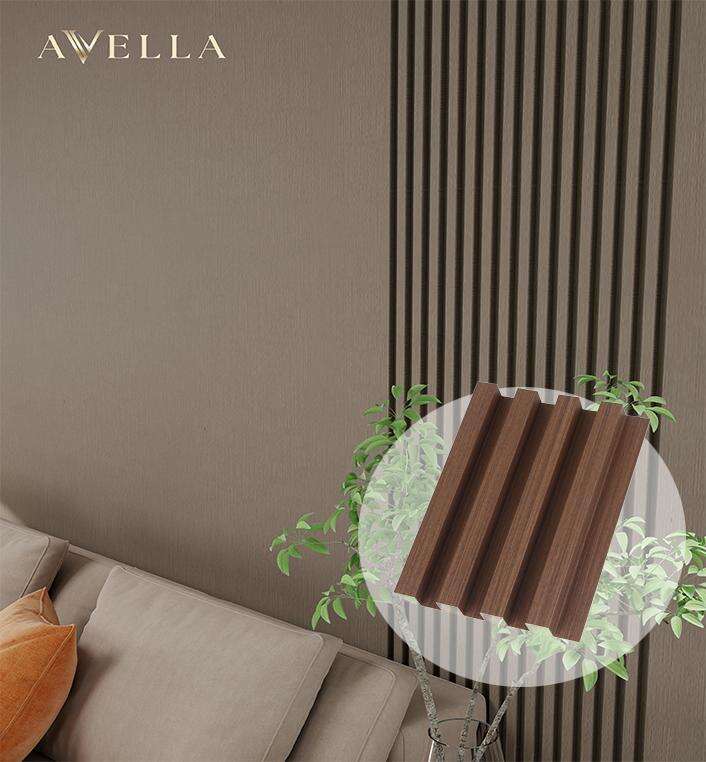

custom grille wall panel factory

A custom grille wall panel factory represents the pinnacle of specialized manufacturing in architectural and decorative elements, serving as a comprehensive production facility dedicated to creating tailored grille solutions for diverse construction and design needs. These sophisticated manufacturing operations combine traditional craftsmanship with cutting-edge technology to produce high-quality wall panels that meet specific client requirements across residential, commercial, and industrial applications. The primary function of a custom grille wall panel factory centers on designing, engineering, and manufacturing bespoke grille panels that serve both functional and aesthetic purposes in modern architecture. These facilities typically house advanced machinery including laser cutting systems, precision welding equipment, powder coating lines, and computer-controlled fabrication tools that enable the production of intricate patterns and designs. The technological infrastructure within these factories incorporates CAD software integration, allowing seamless translation of architectural plans into manufacturable products. Quality control systems ensure each panel meets stringent standards for durability, weather resistance, and structural integrity. The manufacturing process involves multiple stages from initial design consultation through material selection, cutting, forming, finishing, and final inspection. Materials commonly processed include aluminum, steel, stainless steel, and specialized alloys, each chosen for specific performance characteristics. Custom grille wall panel factory operations excel in producing ventilation grilles, decorative screens, privacy panels, security barriers, and architectural features that enhance building facades. Applications span across office buildings, residential complexes, retail spaces, educational institutions, healthcare facilities, and industrial complexes. The versatility of these manufacturing operations allows for customization in dimensions, patterns, materials, finishes, and mounting systems. Advanced surface treatment capabilities include anodizing, powder coating, galvanizing, and specialty finishes that provide corrosion resistance and aesthetic appeal. The factory environment maintains controlled conditions to ensure consistent quality output while adhering to environmental regulations and safety standards. Production capacity typically ranges from small custom orders to large-scale commercial projects, with lead times optimized through efficient workflow management and inventory control systems.