oem wall board factory

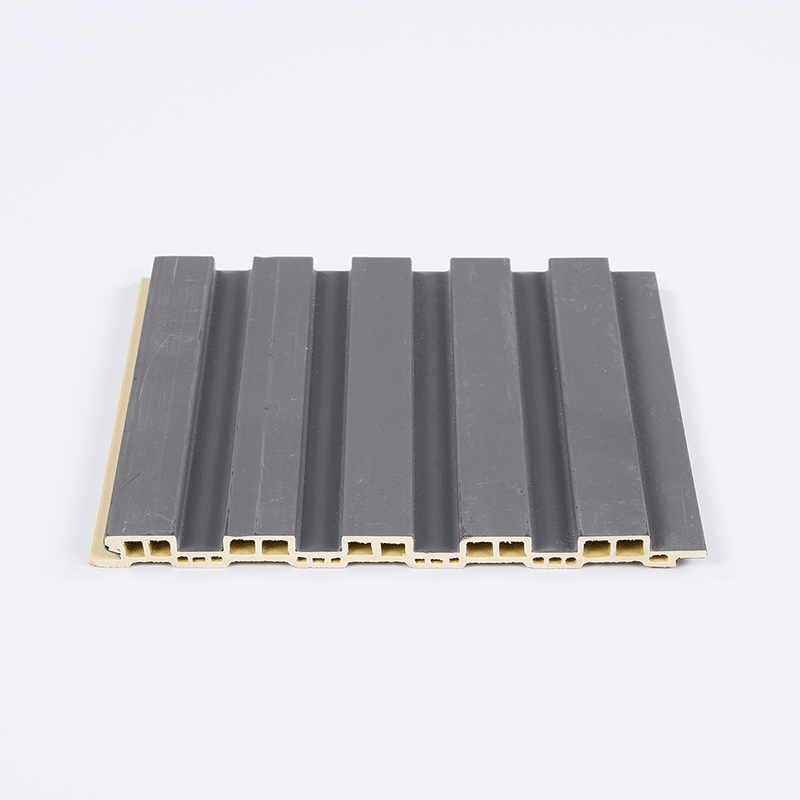

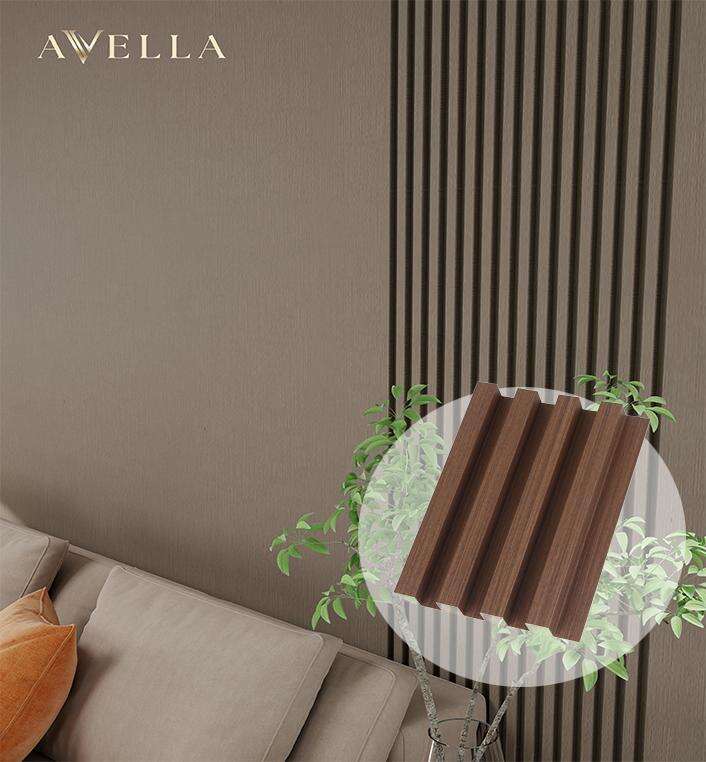

An OEM wall board factory represents a specialized manufacturing facility designed to produce customized wall panels and boarding solutions for diverse construction and interior design applications. These facilities operate under Original Equipment Manufacturer protocols, enabling them to create tailored wall board products according to specific client requirements and industry standards. The primary function of an OEM wall board factory encompasses the complete production cycle from raw material processing to finished product delivery, incorporating advanced manufacturing techniques and quality control systems. The factory typically handles various types of wall board materials including gypsum-based panels, cement fiber boards, composite materials, and eco-friendly alternatives. Modern OEM wall board factory operations utilize sophisticated machinery and automated production lines to ensure consistent quality and efficient output rates. The technological infrastructure includes precision cutting equipment, automated mixing systems, high-pressure forming machines, and specialized drying chambers that maintain optimal curing conditions. Quality assurance protocols within an OEM wall board factory involve continuous monitoring of material composition, dimensional accuracy, surface finish quality, and structural integrity testing. These facilities serve multiple market segments including residential construction, commercial building projects, industrial applications, and renovation markets. The manufacturing process begins with raw material preparation where components are carefully measured and mixed according to proprietary formulations. Advanced forming techniques create uniform panel thickness and surface characteristics while automated handling systems ensure consistent production flow. Environmental considerations play a crucial role in modern OEM wall board factory operations, with many facilities implementing sustainable manufacturing practices and utilizing recycled materials. The production capacity of these factories varies significantly based on facility size, equipment sophistication, and market demand, with larger operations capable of producing thousands of square meters of wall board products daily. Customization capabilities allow OEM wall board factory operations to accommodate specific architectural requirements, fire resistance standards, moisture resistance specifications, and acoustic performance criteria. Strategic partnerships with suppliers ensure reliable access to high-quality raw materials while maintaining competitive pricing structures for end customers.