oem spc wall panel factory

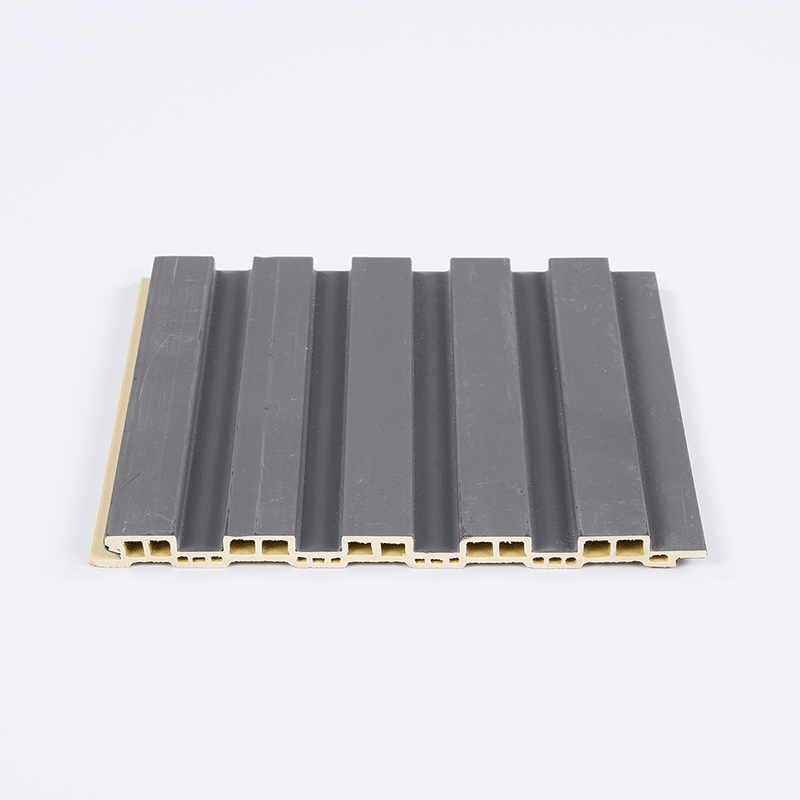

An OEM SPC wall panel factory represents a specialized manufacturing facility dedicated to producing Stone Plastic Composite wall panels under original equipment manufacturer arrangements. These state-of-the-art production centers combine advanced technology with precision engineering to create durable, versatile wall covering solutions for residential, commercial, and industrial applications. The primary function of an OEM SPC wall panel factory involves transforming raw materials including limestone powder, polyvinyl chloride resin, and stabilizers into high-performance wall panels through sophisticated extrusion and pressing processes. The technological infrastructure within these facilities incorporates computerized mixing systems, high-temperature extrusion lines, multi-layer pressing equipment, and precision cutting machinery that ensures consistent product quality and dimensional accuracy. Modern OEM SPC wall panel factories utilize automated production lines capable of producing thousands of square meters daily while maintaining strict quality control standards. The manufacturing process begins with material preparation where limestone and PVC compounds are precisely measured and mixed according to proprietary formulations. Advanced extrusion technology then shapes these materials into continuous sheets before undergoing high-pressure lamination with decorative surface layers. Quality assurance laboratories within each OEM SPC wall panel factory conduct rigorous testing including impact resistance, fire retardancy, moisture absorption, and dimensional stability assessments. These facilities serve diverse market segments including residential construction, hospitality design, healthcare environments, educational institutions, and retail spaces. The versatility of SPC wall panels produced in these factories makes them suitable for bathroom installations, kitchen backsplashes, accent walls, commercial interiors, and exterior cladding applications. Environmental considerations drive many OEM SPC wall panel factories to implement sustainable practices including recycled material utilization, energy-efficient production methods, and waste reduction programs that minimize environmental impact while maximizing operational efficiency.