durable spc wall panel custom production

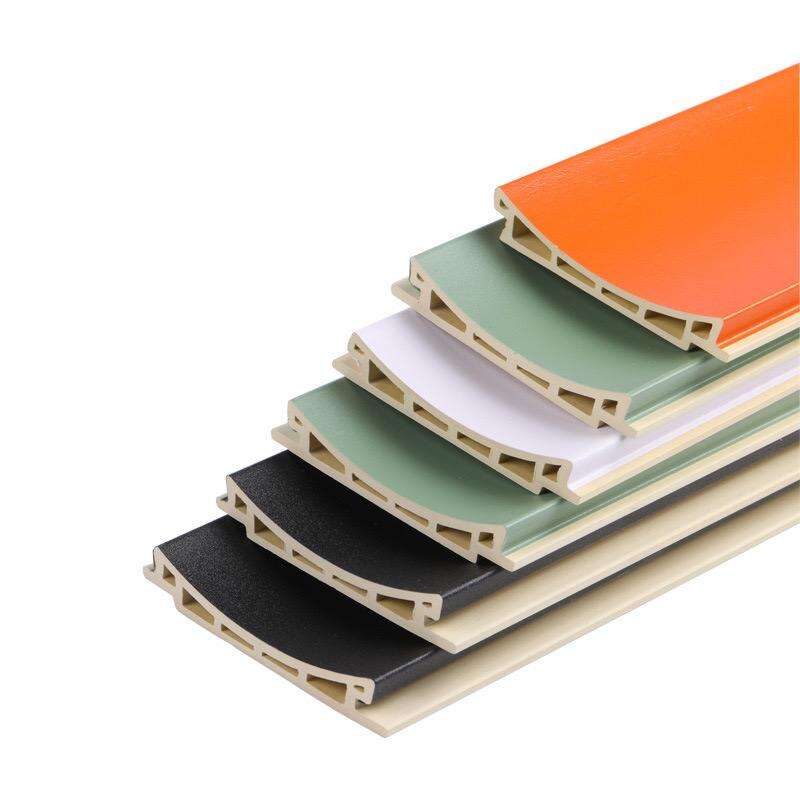

Durable SPC wall panel custom production represents a revolutionary advancement in modern construction and interior design solutions. SPC, which stands for Stone Plastic Composite, combines the durability of stone with the flexibility of plastic to create wall panels that excel in both residential and commercial environments. The custom production process allows manufacturers to tailor these panels according to specific design requirements, dimensional specifications, and aesthetic preferences while maintaining the inherent strength and reliability that SPC materials are known for. The main functions of durable SPC wall panel custom production include providing exceptional moisture resistance, delivering superior impact resistance, offering excellent thermal stability, and ensuring long-term dimensional stability. These panels serve as protective barriers against environmental factors while simultaneously enhancing the visual appeal of interior spaces. The technological features encompass advanced manufacturing processes that utilize high-pressure lamination, precision cutting systems, and specialized surface treatments. The production involves combining limestone powder, polyvinyl chloride, and stabilizers under controlled conditions to create a homogeneous core structure. Custom production capabilities enable manufacturers to incorporate various textures, colors, patterns, and finishes that meet specific project requirements. Applications for durable SPC wall panel custom production span across multiple sectors including healthcare facilities, educational institutions, hospitality venues, retail establishments, and residential properties. These panels are particularly valuable in areas requiring frequent cleaning, high traffic zones, and environments where traditional materials might deteriorate quickly. The versatility of custom production allows architects and designers to implement creative solutions while ensuring compliance with building codes and safety standards. The manufacturing process incorporates quality control measures at every stage to guarantee consistent performance and appearance across entire product batches.